ABOUT US:

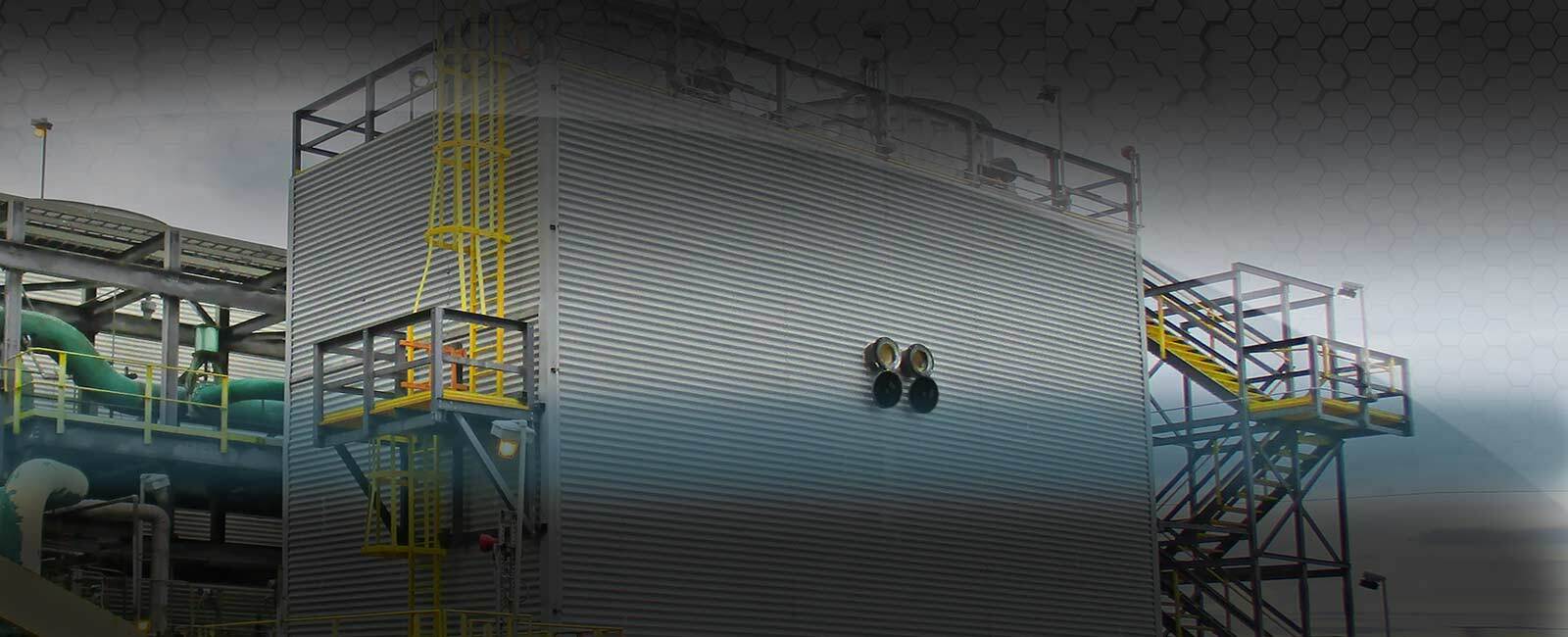

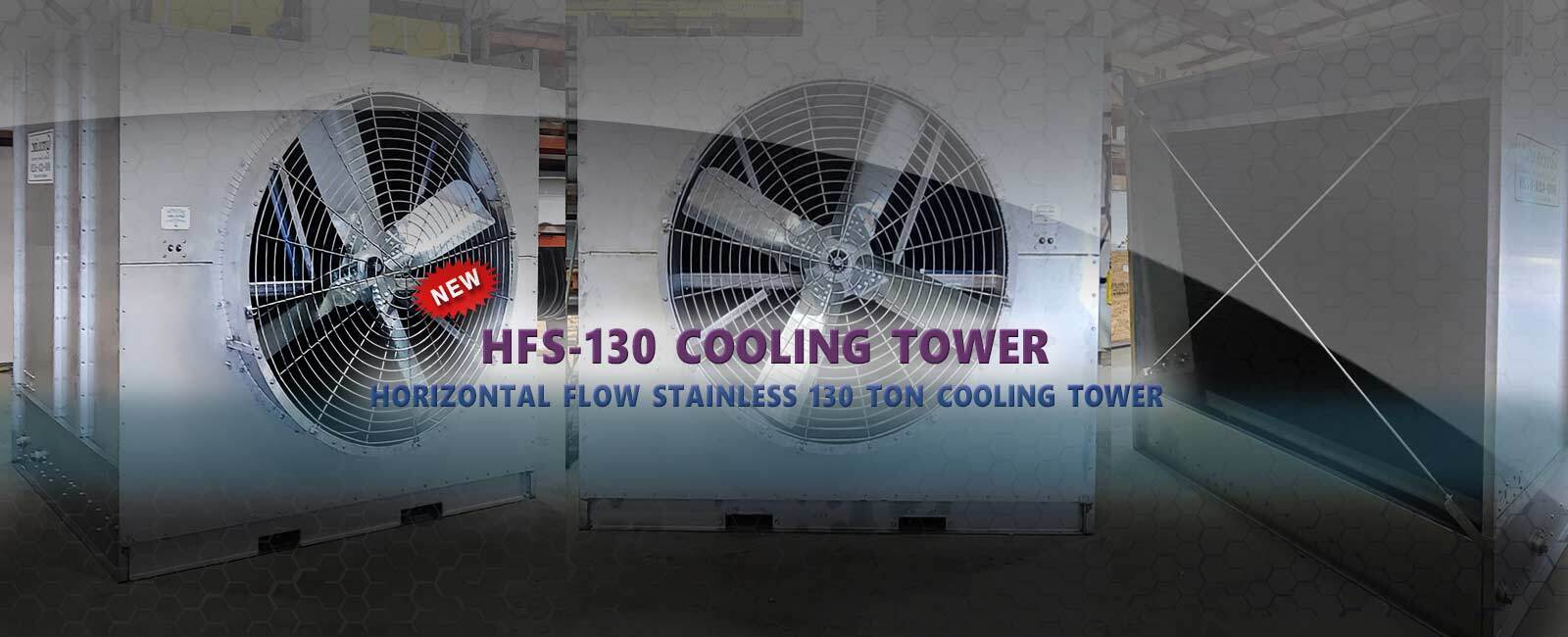

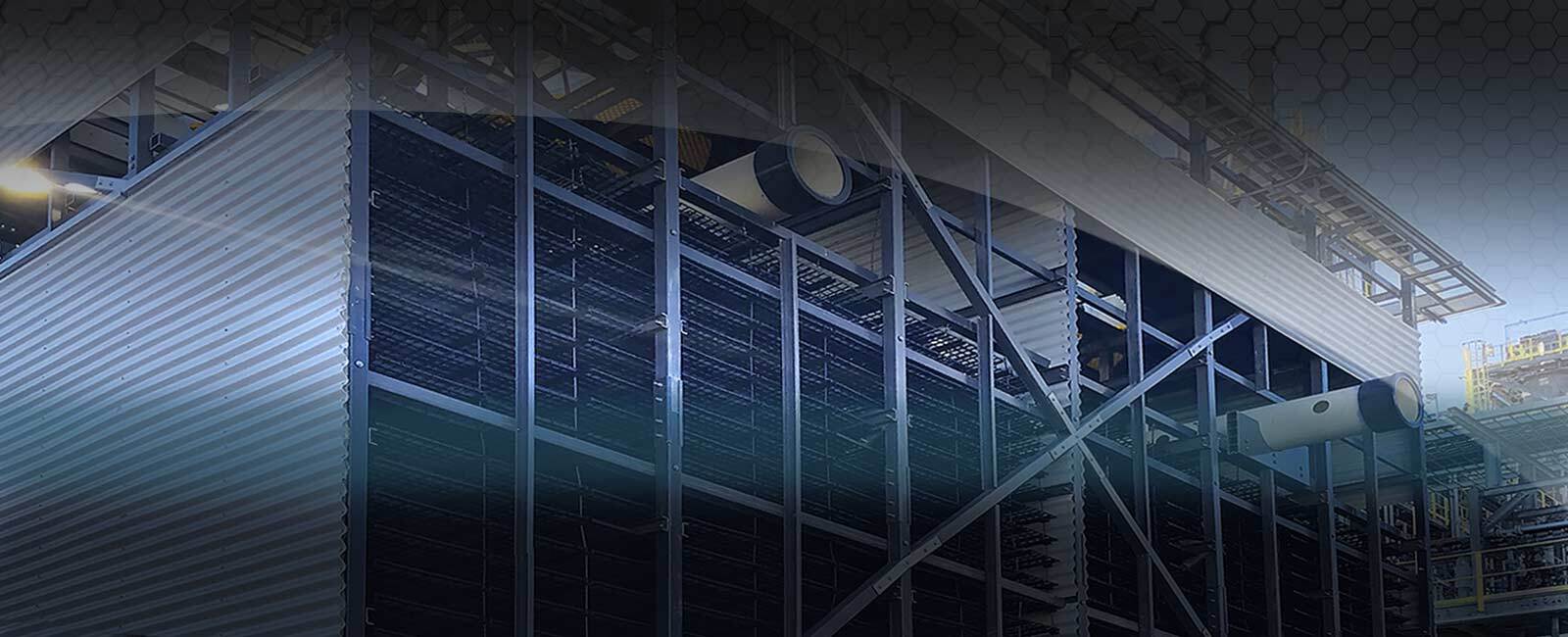

For nearly fifty years, Cyrco, inc. [seer-co] has been providing the most extensive selection of quality cooling tower products and professional services. We construct new field erected (FEP) cooling towers, manufacture metal factory assembled (FAP) cooling towers, and offer cost-saving rebuilds for older cooling towers. We specialize in mechanical and structural repairs, including offering preventative maintenance plans and cleaning services that will extend longevity and performance. As a premiere cooling tower parts retailer, we supply only industry-proven OEM parts along with the widest selection of craftsmanship-built, low-cost, custom metal fabricated aftermarket parts. Cyrco, inc. has also invented two industry-changing products, a “true” Non-Clogging Nozzle, and a FRP Shear Bushing that maximizes strength in composite tubed structures. Our long established history has gained Cyrco, inc. an industry-renowned reputation as being an innovative, single-source cooling tower solutions provider.

Cyrco, inc. "Always" Offers Its Clients:

- Expertly Suited, Craftsmanship Built Products

- Outstanding Customer Service, Second to None

- Safe and Transparent Project Execution

- Low Cost, Metal Fabricated Aftermarket Parts, Custom Built from Heavy Gauge USA Made Steel

REPAIRS and NEW CONSTRUCTION, REGIONS SERVED:

Based in Greensboro, North Carolina, we repair, rebuild, and newly construct field erected and metal cooling towers throughout the Northeast, Mid-Atlantic, Central, Southeast, and Southern regions of the United States. We also offer cooling tower emergency repair services and expedited shipping on a wide selection of OEM and custom fabricated cooling tower parts and FRP products.

OEM PARTS SUPPLIER:

We are an Authorized Reseller for Amarillo Gearboxes, Brentwood Industries, Regal Rexnord Corporation, Moore Axial Flow Fans, and Chart Industries (Hudson Tuf-Lite Fans). We are also a southeast distributor for Amcot Fiberglass Cooling Towers.

As an Authorized Reseller for Brentwood Industries, who is a globally-recognized leader with a long history of designing advanced thermoplastic molding systems, our knowledgeable sales and engineering teams can expertly select the heat transfer media that is most ideal for your specific application. We specialize in splash and film fill media, and drift eliminators, for both field erected and metal cooling towers. We also ship pre-fabricated, fill media packaged kits for any model metal cooling tower.

As a premiere cooling tower parts supplier, we warehouse aluminum and fiberglass fans, fan stacks, gearboxes, drive shafts, fill media, flow control valves, wood and FRP structural material, FRP wall panels, air inlet louvers, water distribution piping, spray nozzles, staircases and stairways, safety swing gates, access doors, fan deck hatchway doors, shut down fan brakes, hardware, and more.

INVENTORS of INDUSTRY-CHANGING PARTS:

CYRCO'S FRP SHEAR BUSHINGS maximizes the structural strength in fiber-reinforced plastic composites tube framing. In tensile strength testing, they outperform all others commonly used and generate more than a 6.0 shear strength factor — more than double the Cooling Tower Institute (CTI) minimum 3.0 standard.

CYRCO'S NON-CLOGGING SPRAY NOZZLES are a solid, one-piece, dispersal-cone spray nozzle that contains no bottlenecks, areas of snag, nor any moving parts which are often the first part to clog, break, or blow out.

METAL FABRICATION of AFTERMARKET PARTS:

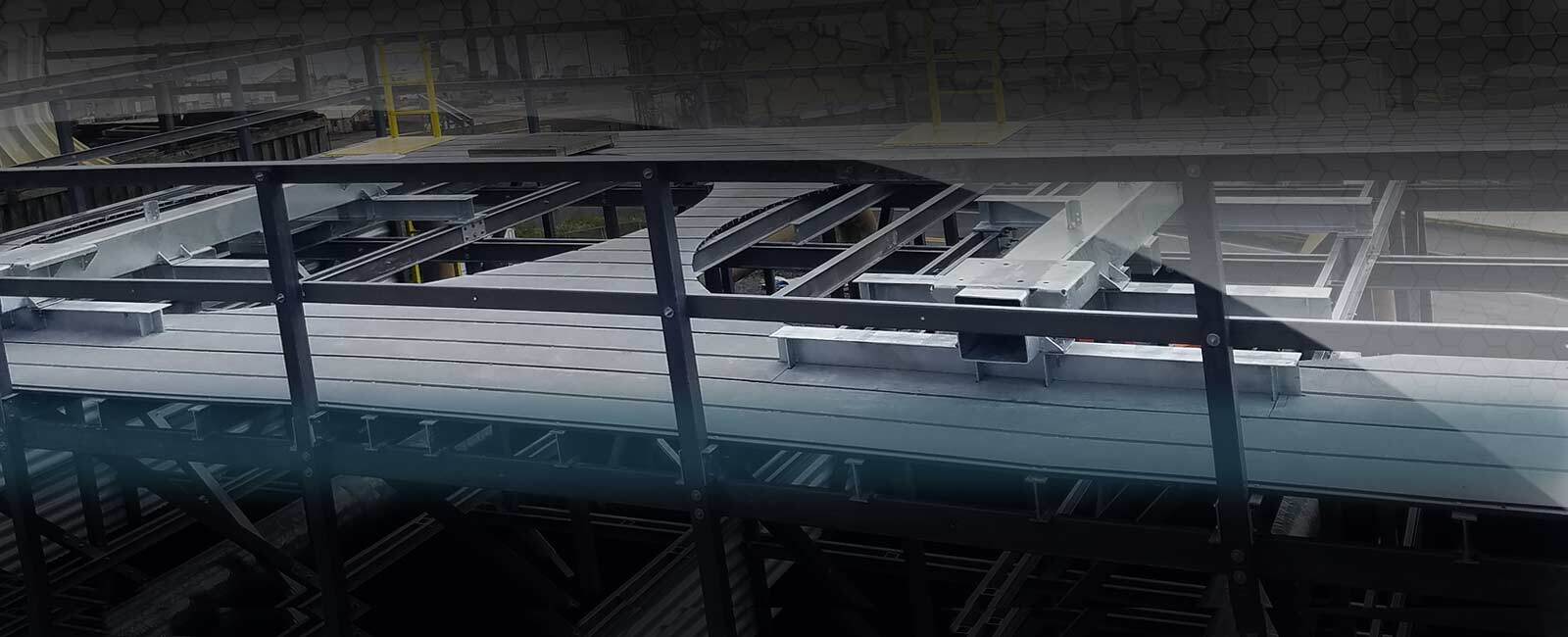

Cyrco, inc. custom metal fabricates a full spectrum of aftermarket cooling tower parts, all of which are constructed from high-quality, U.S.A. made galvanized or stainless steel. Our aftermarket cooling tower parts are compatible for any manufacturers' cooling tower no matter the make, model, or year of construction. They are built-to-spec (or better) drop-in replacements for SPX Marley, Baltimore Aircoil (BAC), Pritchard Pacific, Evaptech, Evapco, or any obsolete, foreign or domestic, cooling tower manufacturer. All parts are expertly metal fabricated in-house using heavy gauge, USA made steel to further assure durability and longevity. Cyrco's custom metal fabricated parts are significantly lower in cost than OEM replacements and available with fast lead times. Known for our craftsmanship, we can professionally install any aftermarket part or offer international and domestic shipping for those outside of our region. We also custom metal fabricate parts and fiber-reinforced polymer (FRP) access/passage products: walkways, stairways, and ladder "pre-fab" kits for ANY industry.

Custom Fabricated Cooling Tower Metal Parts Include:

CLEANING and DISINFECTING SERVICES:

Scheduling an annual cooling tower cleaning will immensely impact the longevity of all structural and mechanical parts while also maintaining optimal performance — it is the key to long-term reliability and cost-savings. Our cooling tower cleaning services removes algae, scale, mud, and contaminants from the exterior wall casing, structural framing, hot and cold water basins, heat transfer media, process water, and mechanical parts. This comprehensive, multi-step cleaning process includes measures to combat dangerous bacteria including Legionella. Micron-filtration of the cold water basin produces crystal clear return cycle water, therefore reducing mechanical stress and bacteria-feeding, organic nutrients. An EPA-approved and eco-friendly surface disinfectant kills viruses and bacteria on contact, and also stunts future bio-growth. Reducing the risk of a potentially deadly outbreak of Legionnaires' Disease while also magnifying the cooling tower's overall potential, makes our cleaning service ideal for retail shopping malls, hotels, corporate offices, schools and universities, medical centers and hospitals, venue complexes, electric power generation companies, milling operations, and product manufacturers.

SAFETY and TRAINING:

We take safety very seriously and consistently maintain an exceptionally low OSHA EMR rating. Our well trained, seasoned, and professional teams stay current with the Cooling Tower Institute (CTI) and industry best practices, hazard identification and abatement, and implementing proper safety protocols, including following site-specific safety requirements. On an annual basis we perform several days of safety and craft training classes for every level of our field employees.

OUR COMMITMENT to YOU:

Whether a single or multi-celled field erected (FEP), or metal factory assembled (FAP) cooling tower, in either cross flow or counter flow configuration, our teams will work diligently with you at every stage of your project. We ensure your complete satisfaction and look forward to the opportunity to serve you.