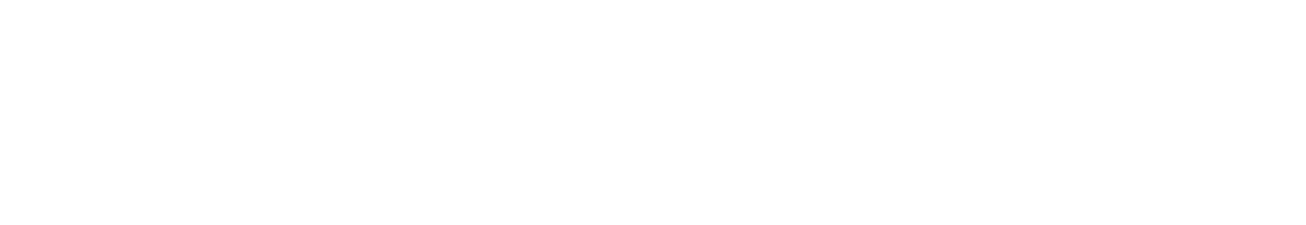

Cyrco's Non-Clogging Spray Nozzles for Solid-Particulate or Viscous, Dirty-Water Counter-Flow Cooling Towers; and/or Other MEP Special Applications

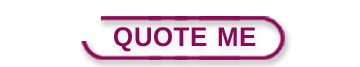

A Simple, Robust, One-Piece Nonclogging Spray Nozzle with No Bottlenecks or Areas of Snag, and No Moving Parts that are the Often the First Part to Clog or Break.

Simplicity!

- No constricting bottlenecks or areas of snag making this the most non-clogging spray nozzle on the cooling tower market

- No moving parts that often clog, are unreliable, and the first part of the nozzle to break; a broken nozzle can cause expensive “water jet” damage to the heat transfer fill media below, costing the client additional time and money in unnecessary repairs

- No areas of snag from the laterial PVC water distribution piping to the exit of the nozzle

- Extremely robust, super simple, one-piece design

Features of Cyrco's Non-Clogging Spray Nozzles:

- For use in counter-flow, field erected cooling towers or other applications with viscous and/or suspended solids process water; or nozzle clogging particulates

- Designed, developed, and manufactured solely by Cyrco, inc.

- Exceptionally high flow rate of gallons per minute (gpm) performance

- Accepts water-reducing, tapered metering orifices to regulate and distribute water evenly throughout the lateral water distribution system

- Cyrco's Nozzle PVC Pipe Adapters (plastic mounts that are colored by PVC tube size), fit standard 2” fine thread and mount flush on 4, 6, or 8 inch PVC water distribution piping

- Spray nozzles are made of chemical and thermal resistant, industrial-grade polypropylene

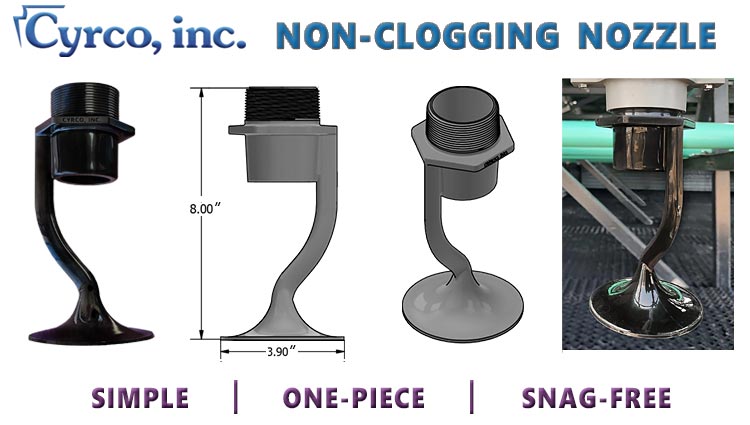

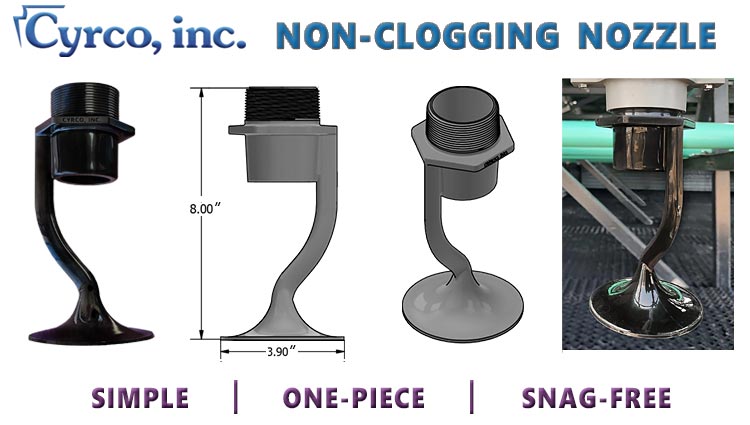

- The bottom dispersal cone splash plate is precisely engineered to provide a uniform fan disbursement of the hot water without gaps or streams

- Easy to install, inspect, and with no additional maintenance needed

- Won't break or blow out under excessive water pressure, induced vibration, or water “hammering” upon start up

- Specifications: Approx. Height 8", Width 4" x 4"

We've REPLACED Missing, Broken, and Clogged Nozzles! The Development of Cyrco's "Truly Non-Clogging" Spray Nozzles. Specifically Designed for Suspended Particulate "Dirty-Water" Counterflow Cooling Towers and/or Other Speciality Applications.

Possessing nearly half-a-century of in-the-field, cooling tower repair and reconstruction services, Cyrco, inc. realized there was a continuous demand for a "true" non-clogging spray nozzle, especially for high-particulate, counter-flow cooling towers. Many of our competitor's non-clogging spray nozzles simply clog or break, even over short periods of time. Those nozzles with moving parts often jam then clog, or jam and then break. The more clogged the nozzle or series of nozzles become, the more the flow rate and pressures of the water distribution system becomes unbalanced.In some areas, the laterial water distrubition piping might be fully clogged and backed up causing additional failures and added mechanical stress. Meanwhile, other areas might experience exceptionally high flow rates which can break, or even "blow out" the spray nozzles from the adapter mounted to the lateral PVC pipe. Nozzles that are broken with missing pieces, or entirely blown out, then can cause expensive "water jet" damage to the heat transfer fill media below. With improperly chosen parts and/or those that are poorly designed, even a newly constructed cooling tower can quickly become thermal and energy deficient, and with expensive challenges to overcome.

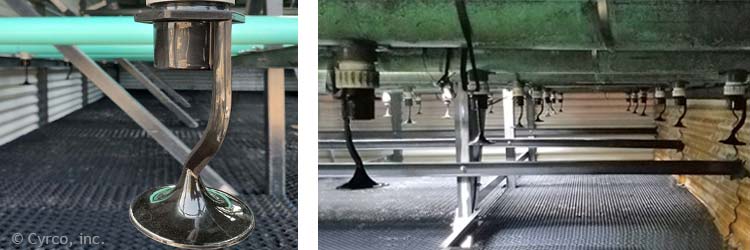

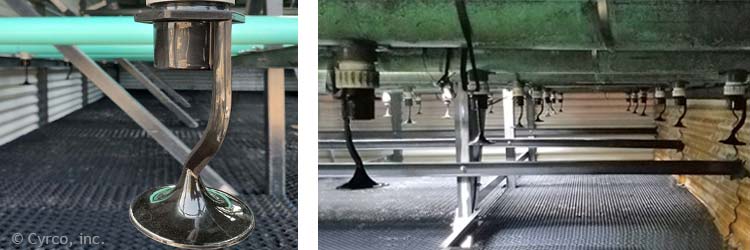

Cyrco's R&D, sales, and engineering teams combined efforts into the long and extensive process of designing and developing a "true" nonclogging spray nozzle. After several prototypes, often with many minor design changes, we finally achieved an ideal design that met our strict endurance and performance standards. Cyrco, inc. is yet proud again to invent and release another revolutionary, industry-changing product.

Cyrco's Non-Clogging Spray Nozzles are the second product that Cyrco has invented and developed, the first being Cyrco's FRP Shear Bushings.

Both are Available for Manufacturer-Direct Purchasing.

Applications and Purpose of Cyrco's NonClogging Spray Nozzles:

For Use in Counterflow Field Erected (FEP) Cooling Towers or Other "Dirty Water" Applications with Viscous and/or Suspended Solid Particulates in the Process Water

- Steel and Metal Mining Mill Cooling Towers

- Paper and Pulp Industry Cooling Towers

- Lake or River Drawn Water Cooling Towers

- Meat Processing Bi-Product Cooling Towers

- Any field erected, contact cooling tower or other applications where the process water contains suspended solid particulates

- Plastics, Rubbers, Wood, Grains, Minerals, Metals, Soil, Silt, Sediments, Grease, Hair, Ash, Fiberglass, or Any Other Nozzle-Clogging Contaminants

RELATED PRODUCTS: