New Construction of Field Erected (FEP) Cooling Towers: Wood or FRP Framing, Crossflow or Counterflow Design | Cyrco, inc.

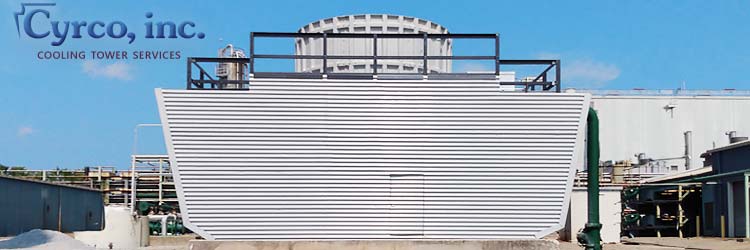

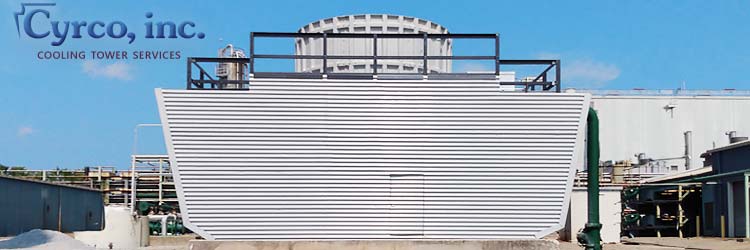

New Field Erected Cooling Towers that are Custom Designed and Built for Robust Durability, Long-Term Operational Reliability, and Maximum Thermal Performance.

For more than 40 years, Cyrco, inc. has been known for it's craftsmanship, quality products, safety record, and our attention to detail. Cyrco's newly constructed field erected (FEP) cooling towers are expertly designed for the client's specific application, maximum thermal performance, and long-term operational reliability, even in the harsh environments and non-ideal conditions.

Our Capabilities and Options for Constructing New Field Erected (FEP) Cooling Towers:

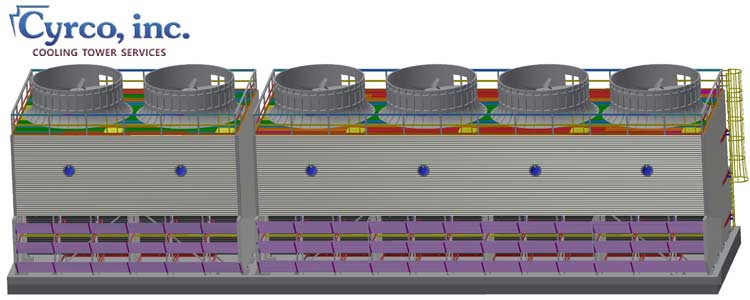

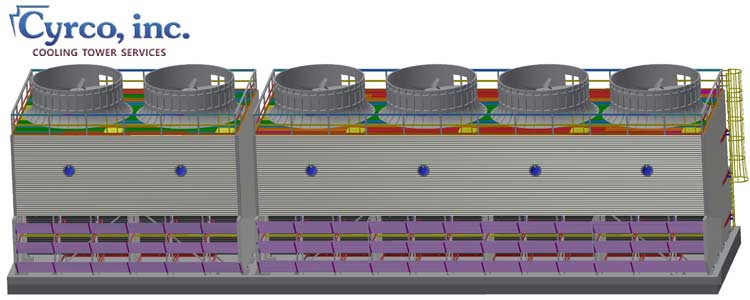

- 3D Designed and Constructed for the Client's Specific Application; Custom Built to the Site's Location; We are Also Cooling Tower Rebuild Specialist.

- Cross Flow and Counter Flow Design Options

- Experts In Heat Transfer Media, Both Film and Splash Fill

- Heat Transfer Media Long-Term Solutions to Difficult Problems (High Temps, Solid Particulates, etc.)

- Framing Options of Industrial-Grade, Pressure Treated Wood or FRP Fiberglass Reinforced Plastic/Polymer Square Tube

- Expert FRP Frame Builders; Cyrco, inc. Designers and Developers of a Patented, FRP Shear Bushing that Maximizes Structural Strength and Out-Performs All Other FRP Bushings on Today's Market

- Access and Passage Products, FRP Fabrication Specialists - Custom Walkways, Catwalks, Stair Towers, Ladder Systems, and More. Cooling Tower FRP Products: Fans, Fan Stacks, Fan Decking, Exterior Side Wall Casing, Square Tube Framing. Safety Upgrades: Self Closing Gates, Caged Ladders, Fan Brakes, High Visibility Products, Toe Boards, and more.

- Hot and Cold Water Basins Custom Fabricated to Any Size and Configuration. Options Include Stainless and Galvanized Steel, or FRP Composites

- Craftsmanship Construction Safely Conducted By Seasoned and Annually Craft Trained Field Technicians. Cyrco, inc. Consistently Maintains an Exceptionally Low OSHA EMR Rating.

- Built with Only the Best of Components from World-Renown Manufacturers

- Low-Cost, Quality, U.S.A. Made Steel, Custom Metal Fabricated Parts Made In-House: Fan Torque Tubes, Mechanical Equipment Supports, Hot Water Distribution Basins, Cold Water Collection Basins, Fan Screens, Wall Casing Panels

Cyrco's new field erected towers are custom engineered for the client’s specific purpose(s), including designing for the site's location and manufacturing purposes. We only use materials that have a long-proven history. If applicable, for cooling tower rebuild projects, the reusing of existing components such as foundations, member structure framing, water distribution systems, electrical wiring, stairways and safety railings, and other costly parts, only further saves our clients additional time and money.

For new field erected cooling towers with fiberglass reinforced plastic (FRP) structural framing, all prefabricated material arrives on-site sorted, marked, and pre-drilled for fast assembly. The fact that Cyrco warehouses a large selection of cooling tower parts and quickly metal fabricates quality, often above OEM spec, parts in house, results in us being extremely efficient. Our clients very much appreciate that Cyrco constructs and completes their cooling towers in a very thorough but timely manner, especially in time sensitive situations.

Using quality USA made metals, Cyrco metal fabricates cooling tower parts including hot and cold water basins, fan torque tubes, mechanical equipment supports, fan guards and screens, and more. Cyrco is also an Authorized Reseller for a host of reputable OEM cooling tower parts manufacturers. These factors again result in our clients saving time and money. In addition, custom metal fabrication and the manufacturing of revolutionary parts, offers Cyrco's clients a wide range of possibilities including non-standard "packaged" cooling towers that often include limitations such as sizing and spacing restrictions, fouling or deforming of fill media, etc. Having to wait upon OEM manufacturers or outside vendors to produce and deliver parts can cause long delays in a cooling tower construction process. Due to Cyrco warehousing and fabricating parts, these factors alleviate our dependency from OEM manufacturers or outside vendors, assuring our client’s cooling tower are built in one continuous momentum.

A Small Sampling of Manufacturing, Services, and Industries in Need of Modern Field Erected Cooling Towers:

- Power Generation Providers

- Renewable Energies: Biomass, Geothermal, etc.

- Oil and Petroleum: Ethanol Refineries

- Chemical Manufacturers

- Food, Beverage, and Meat Processing Plants

- Hospitality: Hotels, Shopping Malls, Hospitals, and Medical Facilities

- Steel Mills and Metal Refineries

- Paper and Pulp Product Industries

- Dried Goods Product Manufacturers

- Schools and Universities

- Cities, Public Works, and Utility Companies

- Sporting Complexes and Music Concert Venues

Our Commitment to Keeping Abreast with Today's Cooling Tower Advancements

The new construction industry for counterflow and crossflow field erected cooling towers is a limited, but an extremely competitive market. With the explosive population growth in recent decades and the trends in rising energy demands from the average consumer, the need for more energy power plants has never been greater. This current multi-billion dollar field erected cooling tower industry is expected to grow more than 50% in the next five years.

Since 1980, Cyrco, inc. has been on the cutting-edge of the cooling tower industry and is poised for this extensive population growth/power generation movement, as well as industrial cooling tower applications. As with any successful business that has been in an industry for more than four decades, a company must adapt and keep abreast with current practices and industry advancements. Cyrco has and continues to expand and further develop in-house fabrication capabilities; implement continuous training for our engineering, sales, and installation teams; updating and applying current technology and computer automated software; only installing time-proven and advanced materials and parts; and stays abreast with the latest Cooling Tower Institute (CTI) standards.

Being pro-active and revolutionary in the cooling tower industry, Cyrco has even modernized and improved some of today’s standard practices in the area of FRP fiberglass cooling tower structural framing. Cyrco developed and manufactures a FRP Square Tube Shear Bushing generates more than a 6.0 shear factor, doubling the 3.0 Cooling Tower Institute (CTI) minimum standard. In tensile strength testing, Cyrco's FRP Bushings out performed all others commonly used. They also mate in the middle to prevent cracked tubes from over-torqued bolts.

Cyrco has also designed a revolutionary, industry-changing product that has overcome a long-hindering, often dead-stop challenge, that has plagued cooling tower owners - how to overcome clogged spray nozzles in counter flow field erected cooling towers when in use with heavy or suspended particulate (aka "dirty water") applications. Cyrco has designed and developed maybe the first ever, successful NON-Clogging Spray Nozzle. Cyrco's simple, one-piece design spray nozzle features no moving, breakable parts, nor any areas of snag, making it "truly" a Non-Clogging Spray Nozzle.

Cyrco has also designed a revolutionary, industry-changing product that has overcome a long-hindering, often dead-stop challenge, that has plagued cooling tower owners - how to overcome clogged spray nozzles in counter flow field erected cooling towers when in use with heavy or suspended particulate (aka "dirty water") applications. Cyrco has designed and developed maybe the first ever, successful NON-Clogging Spray Nozzle. Cyrco's simple, one-piece design spray nozzle features no moving, breakable parts, nor any areas of snag, making it "truly" a Non-Clogging Spray Nozzle.

In addition to our continuous advancements, we offer competitive pricing, optional solutions, superior customer service, and products built with the finest of craftsmanship. Cyrco provides our clients with a solid foundation and a clear direction before any construction even begins. These factors are always fundamental prior to starting any successful project. All of these combined capabilities makes Cyrco extremely versatile and unmatched among today’s cooling tower industry.

Cyrco Constructs New Cross Flow and Counter Flow Field Erected Cooling Towers

Cyrco offers new construction of both counter flow (air is induced from the bottom upwards through the fill media) and cross flow (air is induced through the side walls) field erected cooling towers.

Cyrco offers new construction of both counter flow (air is induced from the bottom upwards through the fill media) and cross flow (air is induced through the side walls) field erected cooling towers.

With counter flow cooling tower designs, they usually require less physical space, however more energy and bigger pumps are required to dispense water through the water distribution system. Pressurized water distribution of counterflow cooling towers makes them less prone to freezing while also breaking up the water into smaller particulates which makes the heat transfer more efficient. Variable water flow can cause challenges to achieve ideal and even distribution, and counterflow cooling towers are typically nosier.

Cross flow cooling towers tend to require less energy to operate the water distribution system, but do require more physical space and a larger fan operation to maximize the heat transfer process. Gravity distributes the water which results in the use of smaller pumps and non-pressurized spray that simplifies variable flow. Allowing air entry through the side makes crossflow cooling towers more susceptible to freezing and dirt build up, especially in sandy environments. Generally, construction costs and long-term costs are lower than counterflow cooling towers, but their design are not always compatible with for the client's application.

Our engineering department with the aide of today’s advanced computer rating software, can ensure optimal cooling tower performance and efficiency to meet your heat rejection targets, tailored to the specific requirements and constraints of your application. We can also determine which design, cross flow or counter flow, is most ideal for your application.

Field Erected Cooling Tower Fiberglass Reinforced Plastic (FRP) Structural Framing, FRP Wall Casing Panel, FRP Fan Decking, FRP Fiberglass Fans, Custom FRP Hot Water Basins, FRP Passage / Access Systems

One of the advancements in today’s construction of field erected cooling towers is the use of pultruded fiberglass reinforced (composites plastics polymers) FRP square tubing for structural tower framing. Pultruded FRP framed towers are lighter and cheaper than steel and unlike traditional wooden framed towers, they will not rot or decay, even after years of direct contact with water. FRP materials are non-conductive, dielectric, fire resistance, impervious to insects, and tolerant to a wide range of corrosive environments.

Over the last few decades, pultruded FRP fiberglass tubing has drastically improved as the composite materials, resins, and ratios have only made the structural integrity stronger and more durable. Compared to wooden framed cooling towers, the benefits of FRP fiberglass framing appear to outweigh wooden framing.

The lighter mass weight of FRP fiberglass also costs less to ship compared to wood, and is not even comparable to the expensive freight shipping of heavy steel.

One of the slight disadvantages of FRP framing is that the material is slightly flexible and more susceptible to excessive winds and storm damage, especially over time. Flexing causes movement and bolt friction to the hole in the FRP fiberglass tube. With back and forth movement, over time the bolt hole size slowly increases at a more rapid pace. This is especially true where contact is made with the bolt’s threading that acts like a metal steel file on plastic fiberglass. Mechanical induced vibration can cause threading hole wear as well. Eventually with continuous vibration, or movement and flexing, the cooling tower becomes more prone to a structural collapse.

Cyrco developed, patented, and manufactures a FRP Square Tube Shear Bushing that fully encloses the bolt which then overcomes the FRP fiberglass hole wear caused by bolt friction. In addition to preventing FRP hole wear, Cyrco’s FRP Shear Bushing mate in the middle which stops the operator from over torquing the bolts and prevents stress cracking to the FRP fiberglass tube. Another advantage of our mating bushings is that the tubular connections act as a guide for the bolts, making for a much faster assembly.

Cyrco developed, patented, and manufactures a FRP Square Tube Shear Bushing that fully encloses the bolt which then overcomes the FRP fiberglass hole wear caused by bolt friction. In addition to preventing FRP hole wear, Cyrco’s FRP Shear Bushing mate in the middle which stops the operator from over torquing the bolts and prevents stress cracking to the FRP fiberglass tube. Another advantage of our mating bushings is that the tubular connections act as a guide for the bolts, making for a much faster assembly.

Results from a series of independent testing performed by the Joint School of Nanoscience and Nanoengeering of North Carolina, outlined that Cyrco’s FRP Shear Bushings clearly outperformed all other commonly used FRP shear bushings. Cyrco’s FRP Shear Bushings created a tower shear service factor of 6.0, which is twice the Cooling Tower Institute (CTI) recommended standard.

In all FRP framing applications, but especially in high wind geographic locations such as coastal plains where hurricanes and tropical storms are frequent, Cyrco strongly recommends the use of our FRP Shear Bushings. With the use of Cyrco’s FRP Shear Bushings, today’s FRP cooling tower’s framing can now become capable of withstanding the most extreme Category 5 hurricanes.

For every field erected cooling tower Cyrco constructs utilizing FRP fiberglass member structure framing, we install our patented FRP Square Tube Shear Bushing.

Wooden Structural Framed, Field Erected Cooling Towers

Traditional wooden framed field erected cooling towers are still practical for applications in today’s market of newly constructed cooling towers. Wooden framed cooling towers are the lowest cost to construct, even in times when lumber prices are considerably high. Cyrco, inc. uses industrial-grade acid copper chromate (ACC) pressure treated Douglas Fir or Redwood lumber for all wooden cooling tower construction.

Traditional wooden framed field erected cooling towers are still practical for applications in today’s market of newly constructed cooling towers. Wooden framed cooling towers are the lowest cost to construct, even in times when lumber prices are considerably high. Cyrco, inc. uses industrial-grade acid copper chromate (ACC) pressure treated Douglas Fir or Redwood lumber for all wooden cooling tower construction.

In high moisture areas and/or areas of direct water contact, the wooden framing eventually becomes susceptible to rot and decay and will need some repair or replacement. Wooden framed towers are much easier for a qualified technician to maintain and inspect as they can physically see and/or with the use of hand tools, probe and detect areas of decay and rot. This is one advantage over FRP framing for with FRP framing, the tasks of identifying areas of weakness can be extremely difficult as the signs are not always clearly evident, especially if the deterioration of the fiberglass is inside the FRP tubing.

Maintenance

Our field erected cooling towers are built to offer optimal thermal performance, durability, and years of operation with little to no maintenance, however as with all mechanical equipment, to achieve the best performance and longevity of your cooling tower, we offer annual and bi-annual inspections and mechanical service plans. This service assist our clients with planning, budget forecasting, and scheduling mechanical replacement prior to an equipment failure and a forced or unscheduled shut down. This is a cost effective solution for assurance that your cooling tower continues operating at peak performance and with the benefit of extending years of additional use from your newly constructed cooling tower.

RELATED PRODUCTS:

Cyrco offers new construction of both counter flow (air is induced from the bottom upwards through the fill media) and cross flow (air is induced through the side walls) field erected cooling towers.

Cyrco offers new construction of both counter flow (air is induced from the bottom upwards through the fill media) and cross flow (air is induced through the side walls) field erected cooling towers.

Traditional wooden framed field erected cooling towers are still practical for applications in today’s market of newly constructed cooling towers. Wooden framed cooling towers are the lowest cost to construct, even in times when lumber prices are considerably high. Cyrco, inc. uses industrial-grade acid copper chromate (ACC) pressure treated Douglas Fir or Redwood lumber for all wooden cooling tower construction.

Traditional wooden framed field erected cooling towers are still practical for applications in today’s market of newly constructed cooling towers. Wooden framed cooling towers are the lowest cost to construct, even in times when lumber prices are considerably high. Cyrco, inc. uses industrial-grade acid copper chromate (ACC) pressure treated Douglas Fir or Redwood lumber for all wooden cooling tower construction.