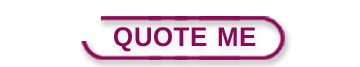

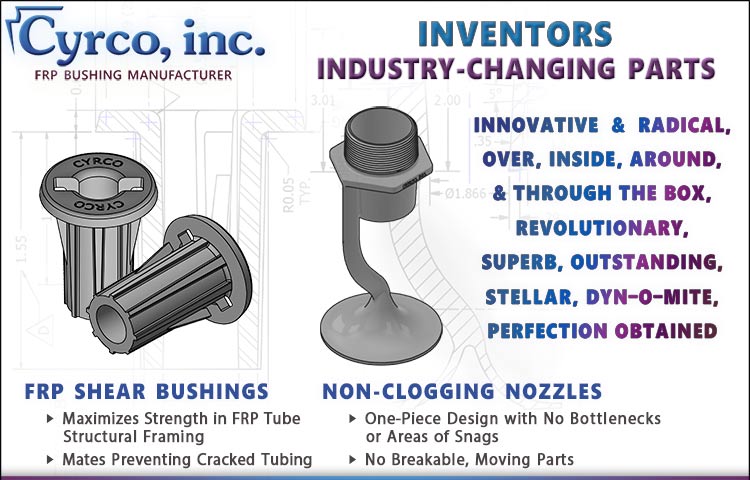

Cyrco's FRP Shear Bushings Maximizes Strength at Bolted Connections in Fiber-Reinforced Plastic Composites Square Tube Structural Framing

Generates More than a 6.0 Shear Service Factor, Doubling the Cooling Tower Institute (CTI) 3.0 Minimum Standard. In Tensile Strength Testing, Cyrco's FRP Bushings Outperforms All Others Commonly Used. Also Mates Preventing Cracked Tubing.

- Maximizes load-bearing strength in fiberglass reinforced plastic (FRP) composites, structural tubed framing.

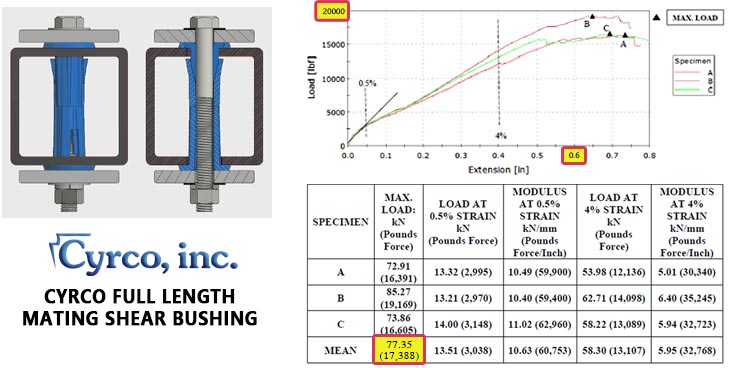

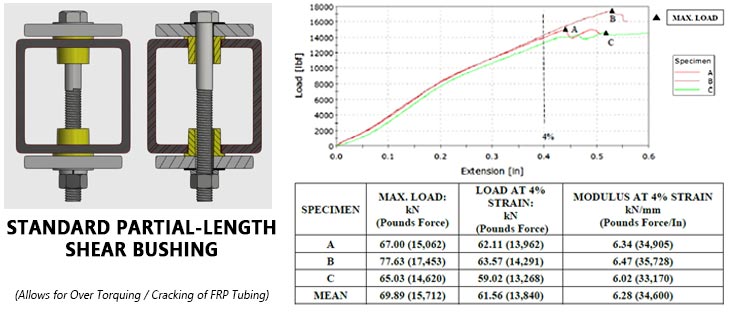

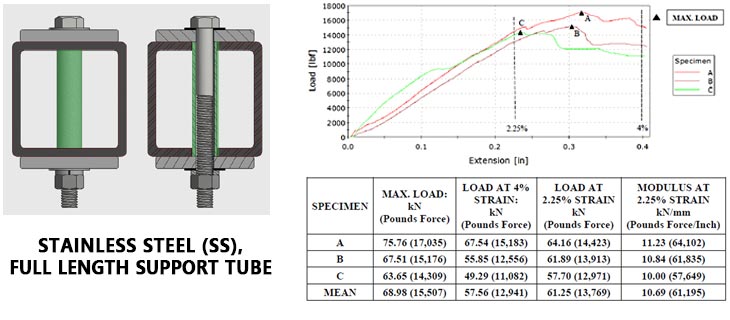

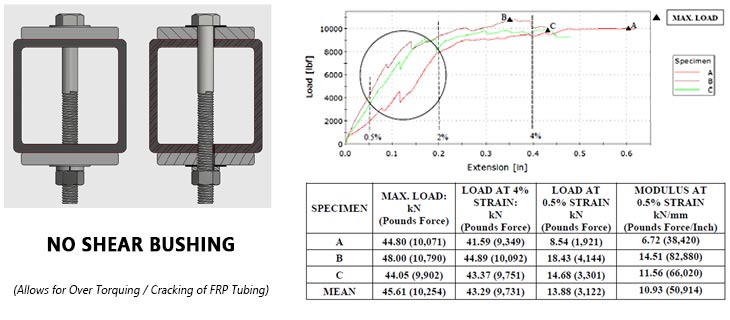

- In tensile strength testing, Cyrco's FRP Shear Bushings out-performed all other commonly used.*

- Generates more than a 6.0 Shear Service Factor, doubling the minimum 3.0 Cooling Tower Institute (CTI) standard.* Cooling towers structural framing becomes capable of withstanding the most intense of Category 5 hurricanes.

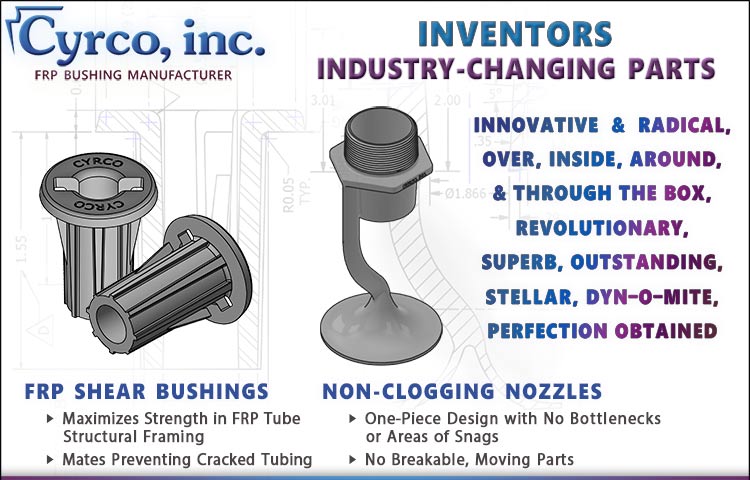

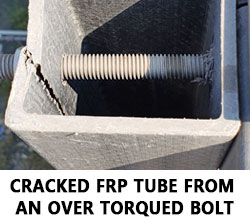

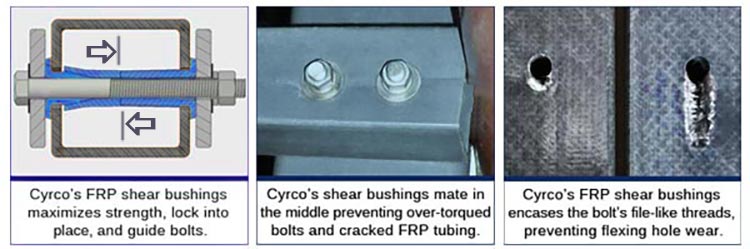

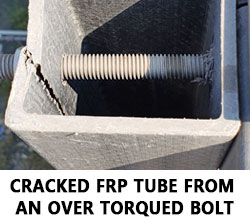

- Mating bushings as the two ends meet in the middle (mates) which doubles the torque safety factor, immensely reducing FRP cracked tubing from over torqued bolts.

- Encases the bolt’s file-like threads, protecting the FRP tube and preventing hole wear that occurs when induced (pumps, motors, fans, foot traffic, etc.) or natural (wind, seismic activity, flowing water, etc.) vibrations are present. Over time, as the hole size increases, the deformation accelerates at a more rapid pace, weakening the structural integrity.

- Guides bolts quickly from entrance to exit holes therefore greatly reducing build times.

- Bushings are self-locking into place allowing for pre-assembly.

- Available in four commonly used sizes: 3/8" bolt 3" tube, 1/2" bolt 3" tube, and 1/2" bolt 3.5" tube. (09.5mm bolt 76.2mm tube, 09.5mm bolt 88.9mm tube, 12.7mm bolt 76.2mm tube, and 12.7mm bolt 88.9mm tube).

- Designed, developed, and manufactured by Cyrco, inc.; patented.

- Buy manufacturer-direct; pricing also available for retailers and wholesalers.

- Made of chemical and thermal resistant, industrial-grade, quality polymer; Made in the U.S.A.

- Pre-installation available through major FRP cooling tower retailers.

- Beneficial to any industry utilizing fiberglass reinforced plastic (FRP) composites tubing for structural framing applications including aerospace, marine, and transportation.

*Joint School of Nano–Science and Nano–Engineering of North Carolina A&T State University

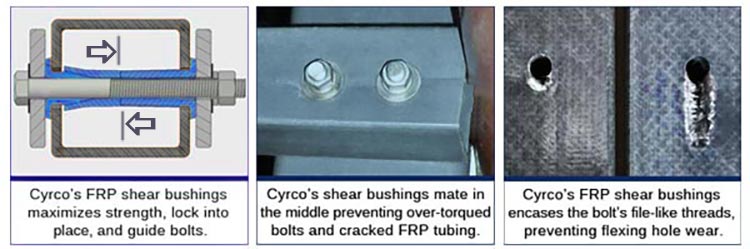

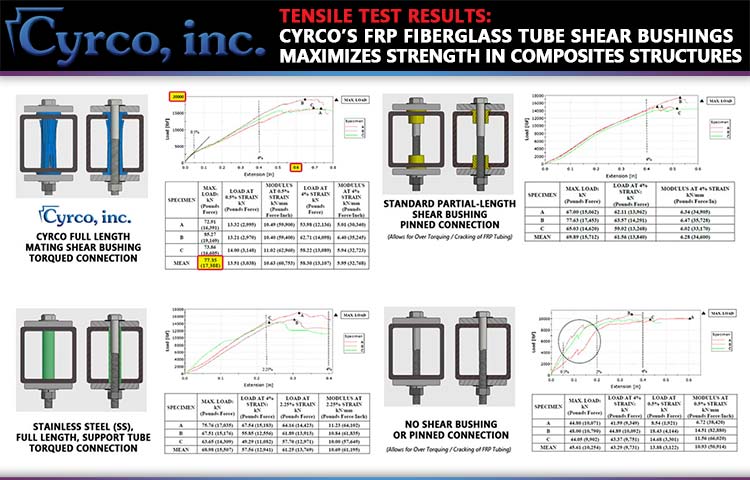

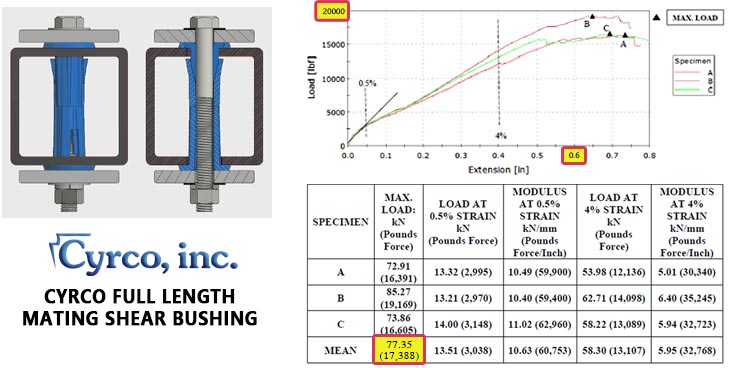

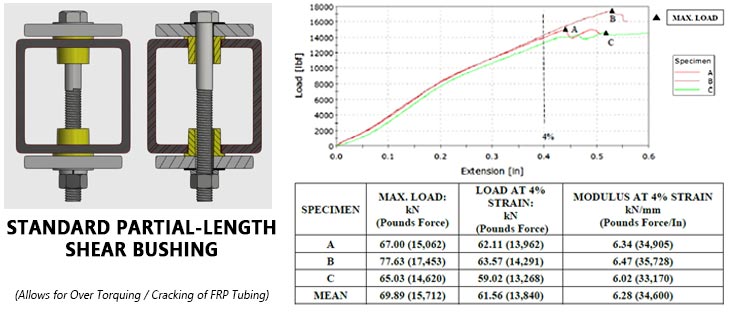

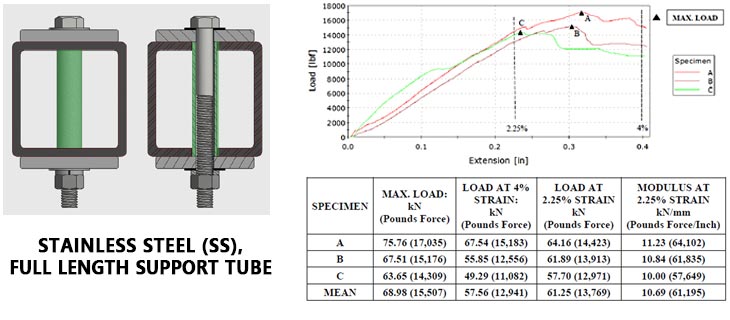

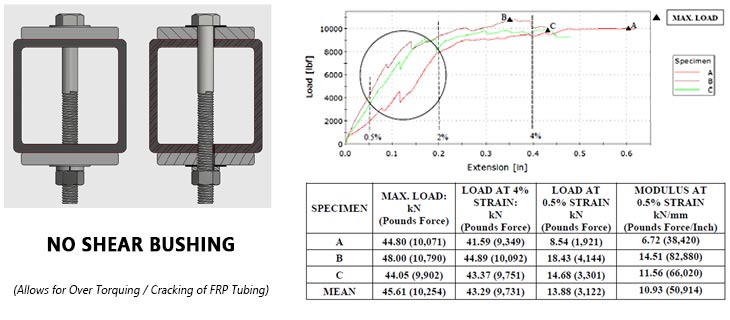

Tensile Strength Tests Results (Released) of FRP Shear Bushings Used at Bolted Connections in FRP Fiberglass Square Tube Structural Framing. Conducted by the Joint School of Nano–Science and Nano–Engineering of North Carolina A&T State University

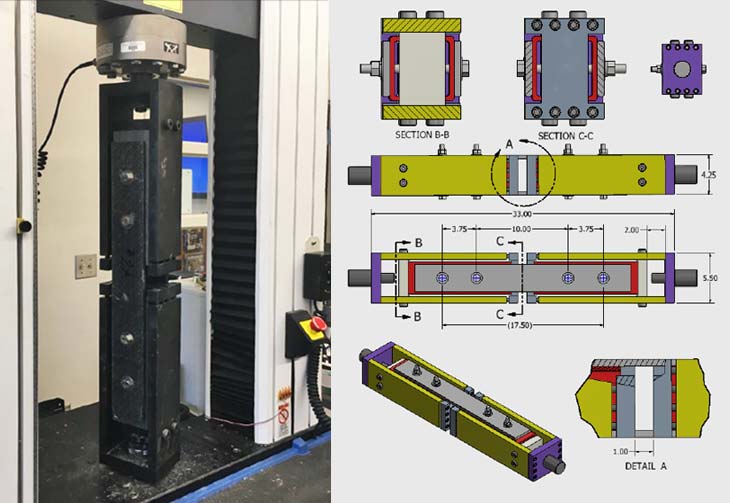

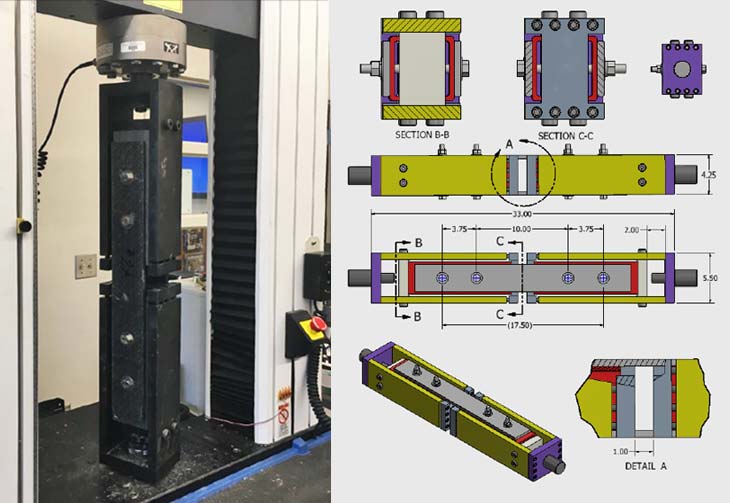

Tensile Strength Testing Methodology of Bolted Joints in FRP Fiberglass Square Tube Connections. Detailed and Thorough Tensile Testing was Conducted by the Joint School of Nano–Science and Nano–Engineering of North Carolina A&T State University

This thorough and comprehensive testing targeted the more severe tensile loading rather than compression loading in composites joints. Composites joints subjected to compression loading are less sensitive to joint geometry and are generally stronger than joints subjected to tensile forces. Members are loaded in the lengthwise orientation according to the direction of the pultrusion to utilize the maximum tensile strength available from the FRP. All edge distances exceed the minimum recommendations relative to bolt diameter. As such, the predicted failure mode is bearing failure, rather than failure by tension or shear out. Bearing failure is caused by the bearing pressure forces from the bolt applied to the hole boundary producing delamination of the composites. Historically, bearing failure has been defined as 4% elongation of the bolt-hole diameter. No appreciable load capacity can be expected after the 4% diameter elongation is met. Any further elongation of the holes only allows the structure to become loose and unstable.

The FRP materials used for this test are fire retardant polyester, compliant with the Cooling Tower Institute (CTI) industry standards. Cross-sectional dimensions of the tubes are 88.9 mm square x 6.4 mm thick (3.5" square x 0.25" thick). Cross-sectional dimensions of the straps are 76.2 mm wide x 9.6 mm thick (3.0" wide x 0.38" thick). Fastener materials are all of S30400-grade stainless steel, Ø12.7 mm-13 (ؽ"-13) UNC. One flat washer is placed below the head of the bolt. One flat washer and one helical locking washer is placed under the nut. All threads are lubricated with a graphite-petrolatum anti-seize compound.

Read the Full Tensile Testing Report:

Read the Full Tensile Testing Report:

BOLTED STRUCTURAL CONNECTIONS IN FIBERGLASS MATERIALS (PDF)

More About Cyrco's FRP Shear Bushings and Today's FRP Composites Square Tube Structural Framing in Modern Construction; Ideal for Wet Conditions such as Water Treatment Centers, Sewer Processing Plants, Boating and Dock Marinas, Aerospace, Transportation, and more.

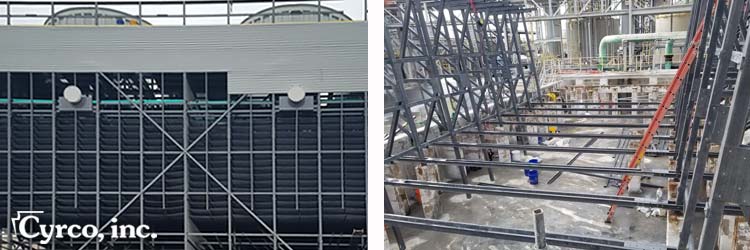

Like many engineering and structural industries, one of the major advancements in today’s construction of cooling tower framing is the use of polymer composites also known as fiberglass reinforced polymer (FRP) structural tubing. Pultruded FRP fiberglass structure members are lighter and cheaper than steel, especially when factoring in expensive freight shipping. Unlike traditional wooden framed towers, even after decades of direct contact with water, FRP members will not decay like wood in high moisture environments, such as that of inside a cooling tower.

A slight disadvantage of FRP framing is that the FRP tubing is a semi-flexible material and when natural elements or induced vibrations are present (wind, motor vibration, foot traffic, etc.) the intregrity of the structural framing can over time become greatly jeopardized.

Flexing causes movement and bolt friction to the drilled hole in the FRP tubing. With back and forth movement, over time the bolt hole size slowly increases. As the hole size increases, the more rapid the pace becomes. This is especially true where contact is made with the bolt’s "file-like" threading against the softer, plastic composites tubing. Vibrations from running motors and mechanical equipment, nature (storms, wind, seismic, etc.), or other induced vibrations such as foot traffic, can also cause bolt hole wear in the FRP tubing. Eventually with continuous movement and flexing the cooling tower becomes more prone to a structural collapse.

Cyrco developed, patented, and manufactures a FRP Shear Bushing that mate in the middle, preventing the installer from over torquing the bolts that can create permanent "weak link" stress cracks in the FRP tubing. The joined mating also prevents under-tightened, loose nuts that often unthread and fall to the ground, as the installer knows when to stop tightening as the nut can not tighten any further. With the use of Cyrco's FRP Shear Bushing the nut and bolt are tightened within an ideal torque range, not over torqued, nor under-threaded. Another advantage of our mating bushings is that the tubular connections act as a pass through guide for the bolts, making for a much faster, rapid assembly.

Cyrco developed, patented, and manufactures a FRP Shear Bushing that mate in the middle, preventing the installer from over torquing the bolts that can create permanent "weak link" stress cracks in the FRP tubing. The joined mating also prevents under-tightened, loose nuts that often unthread and fall to the ground, as the installer knows when to stop tightening as the nut can not tighten any further. With the use of Cyrco's FRP Shear Bushing the nut and bolt are tightened within an ideal torque range, not over torqued, nor under-threaded. Another advantage of our mating bushings is that the tubular connections act as a pass through guide for the bolts, making for a much faster, rapid assembly.

Results from a series of independent testing performed by the Joint School of Nano–Science and Nano–Engeering of North Carolina, outlined that Cyrco’s FRP Shear Bushings clearly outperformed all other commonly used FRP shear bushings. Cyrco’s FRP Shear Bushings generated a shear service factor of more than a 6.0, which is more than twice the Cooling Tower Institute (CTI) 3.0 recommended standard.

In all FRP fiberglass bolted connected member structural framing applications, especially in excessive weight-stressed, or high wind geographic locations such as coastal plains where hurricanes and tropical storms are frequent, Cyrco strongly recommends the use of our FRP Shear Bushings.

Composites World, an industry-leading source for reliable news and information about fiber-reinforced composites manufacturing, recently featured Cyrco's FRP Bushings in a product spotlight article titled:

Composites World, an industry-leading source for reliable news and information about fiber-reinforced composites manufacturing, recently featured Cyrco's FRP Bushings in a product spotlight article titled:

"Cyrco, inc. Showcases FRP Bushings for Maximizing Composite Structural Integrity"

With FRP fiberglass composites materials becoming ever so more present in an abundant of everyday engineering and structural industries, from marine to aerospace, Cyrco's FRP Fiberglass Tube Shear Bushings are not just limited or beneficial to the cooling tower industry.

RELATED PRODUCTS:

Read the Full Tensile Testing Report:

Read the Full Tensile Testing Report:

Cyrco developed, patented, and manufactures a FRP Shear Bushing that mate in the middle, preventing the installer from over torquing the bolts that can create permanent "weak link" stress cracks in the FRP tubing. The joined mating also prevents under-tightened, loose nuts that often unthread and fall to the ground, as the installer knows when to stop tightening as the nut can not tighten any further. With the use of Cyrco's FRP Shear Bushing the nut and bolt are tightened within an ideal torque range, not over torqued, nor under-threaded. Another advantage of our mating bushings is that the tubular connections act as a pass through guide for the bolts, making for a much faster, rapid assembly.

Cyrco developed, patented, and manufactures a FRP Shear Bushing that mate in the middle, preventing the installer from over torquing the bolts that can create permanent "weak link" stress cracks in the FRP tubing. The joined mating also prevents under-tightened, loose nuts that often unthread and fall to the ground, as the installer knows when to stop tightening as the nut can not tighten any further. With the use of Cyrco's FRP Shear Bushing the nut and bolt are tightened within an ideal torque range, not over torqued, nor under-threaded. Another advantage of our mating bushings is that the tubular connections act as a pass through guide for the bolts, making for a much faster, rapid assembly.